New polypropylene material made in Ningbo

- Details

- Category: Ningbo Business

- Published: Monday, 14 August 2023 14:47

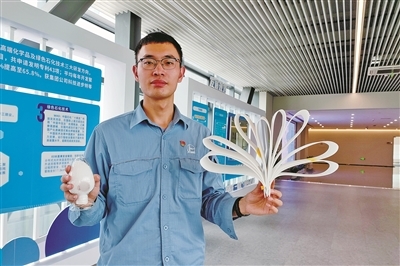

White in color, the particles look ordinary, but they have such advantages as having high energy recovery ability,

being strongly resistant to chemicals, having good insulation, and being environmentally friendly.

“This sample is a kind of high melt strength polypropylene, a domestic polypropylene product that can be used for molding and foaming, with global leading performance. It was developed by the research team of Zhenhai Refining and Chemical Company and Sinopec (Ningbo) New Materials Research Institute after several years of research and development.” said Guo Xiaoshuai, a researcher at Sinopec (Ningbo) New Materials Research Institute. The high-melt strength polypropylene can be used for the new-energy vehicles as a buffer and insulation material for the new-type power batteries, or as the light and high-strength cover material for spare tires.

As the “heart” of new-energy cars, power batteries provide forward mobility for vehicles. “The bottom guard foam made of high melt strength polypropylene can absorb energy, resist impact, and better protect the blade type battery of new energy vehicles.” said Guo Xiaoshuai. The research team of Zhenhai Refining and Chemical Company and Sinopec (Ningbo) New Materials Research Institute uses advanced polymerization control technology to improve the melt strength of polypropylene products, and the material can be effectively mass produced.

Based on innovative achievements, Zhenhai Refining and Chemical Company has so far produced over 10,000 tons of this polypropylene products for the new energy vehicle industry chain.

The comfort of new-energy vehicles has now become the main concern of consumers. With the focus on the project of “development and application of lightweight materials technology for green and environmentally friendly vehicles”, Sinopec (Ningbo) New Materials Research Institute has not only developed high melt strength polypropylene products, but also innovatively launched the polypropylene with “three highs and two lows”.

The term “three highs and two lows” refers to high fluidity, high rigidity, and high toughness, as well as low odor and low volatile organic compounds. “The polypropylene with “three highs and two lows” is more favored by the new energy vehicle industry chain, being used as automotive interior materials for dashboard, dashboard glove box, central storage box, and door panel frame,” said Guo Xiaoshuai.

High crystalline polypropylene is an important kind of polypropylene product with “three highs and two lows”. The research team of Zhenhai Refining and Chemical Company and Sinopec (Ningbo) New Materials Research Institute adopts special catalysts to endow the polypropylene product with high fluidity and rigidity, and further optimizes and upgrades the production process, empowering it with low odor and low volatile organic compound. As of now, Zhenhai Refining and Chemical Company has produced over 100,000 tons of polypropylene products with “three highs and two lows”.

Technological innovative leads to high-quality development of industries. Sinopec (Ningbo) New Materials Research Institute is a major technological innovation platform and high-tech industry incubation base jointly built by Sinopec and Ningbo Municipal Government, and managed by Zhenhai Refining and Chemical Company. “Faced with the rapid development of new energy vehicles, we will seize industrial opportunities and continuously improve and upgrade our polypropylene products.” said a related person in charge from Sinopec (Ningbo) New Materials Research Institute